Personalized Healthcare

We develop personalized drug delivery strategies for chronic conditions, to improve quality and safety of care through automation. Our work is strongly interdisciplinary and harnesses the strength of model-based automatic control and machine learning, two fields that play a vitally important role in engineering but that tend to have different goals and tools if taken separately. Working at the intersection of these two fields makes it possible to personalize treatments and to adapt modeling, data analysis and automation of complex biomedical systems to real-life scenarios in order to improve health outcomes and minimize risks and harms to patients.

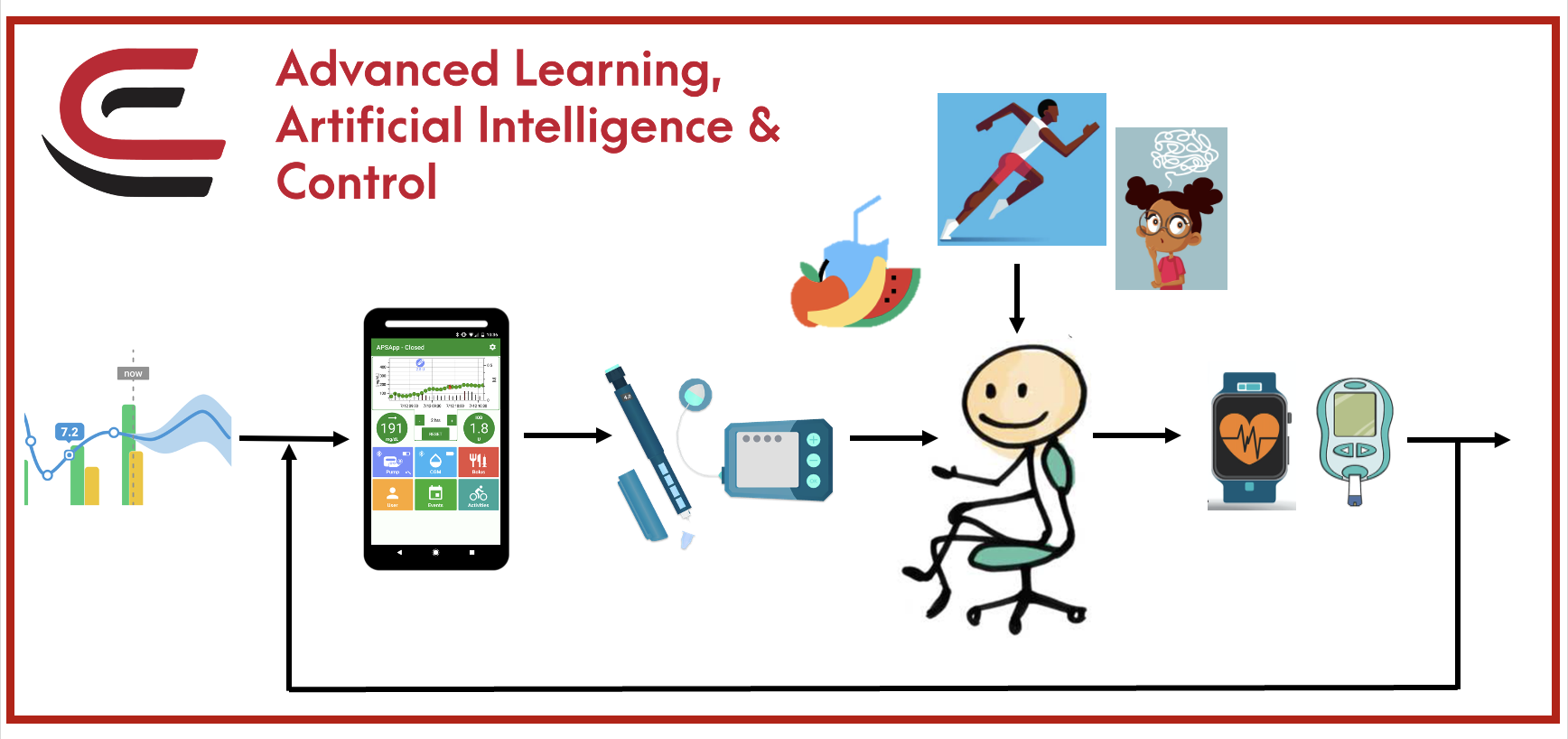

Type 1 diabetes (T1D) is a prime candidate for the development of a treatment strategy using biomedical control. In this disease, the auto-immune destruction of the beta cells in the pancreas prevent the body from producing insulin, a hormone that is required for the glucose homeostasis feedback loop. The current standard of treatment is for people with T1D to measure their blood glucose concentration several times per day and manually deliver corresponding doses of insulin.

In our lab, we aim at artificially recreating the glucose control feedback loop using a combination of medical devices, wearable sensors and a smartphone, to realize a fully automated insulin delivery system. A short video offering a glimpse into our research and ideas for the future in this space can be accessed here.

Ongoing Projects:

- Data-Enabled Neural Multi-Step Predictive Control (DeMuSPc): a Learning-Based Predictive and Adaptive Control Approach for Complex Nonlinear Systems (Founding source: NSF – press release) [overview video]

- First-Principles Informed Data-Enabled Predictive Digital Twin of Human Physiology (Founding source: NSF – press release) [overview video].

- Learning blood glucose predictors with artificial neural networks for decision support systems [overview video] and closed-loop glucose control [overview video].

- Decision support for insulin dosage optimization in multiple-daily-injections therapy for people with type 1 diabetes.

- Development of personalized insulin infusion failure detection algorithms combining tissue counter pressure and blood glucose data for closed-loop diabetes management, in collaboration with Diatech Diabetes (Founding source: NIH R43DK130036 – press release, JDRF IDDP).

Safe Autonomy for Advanced Air Mobility (AAM)

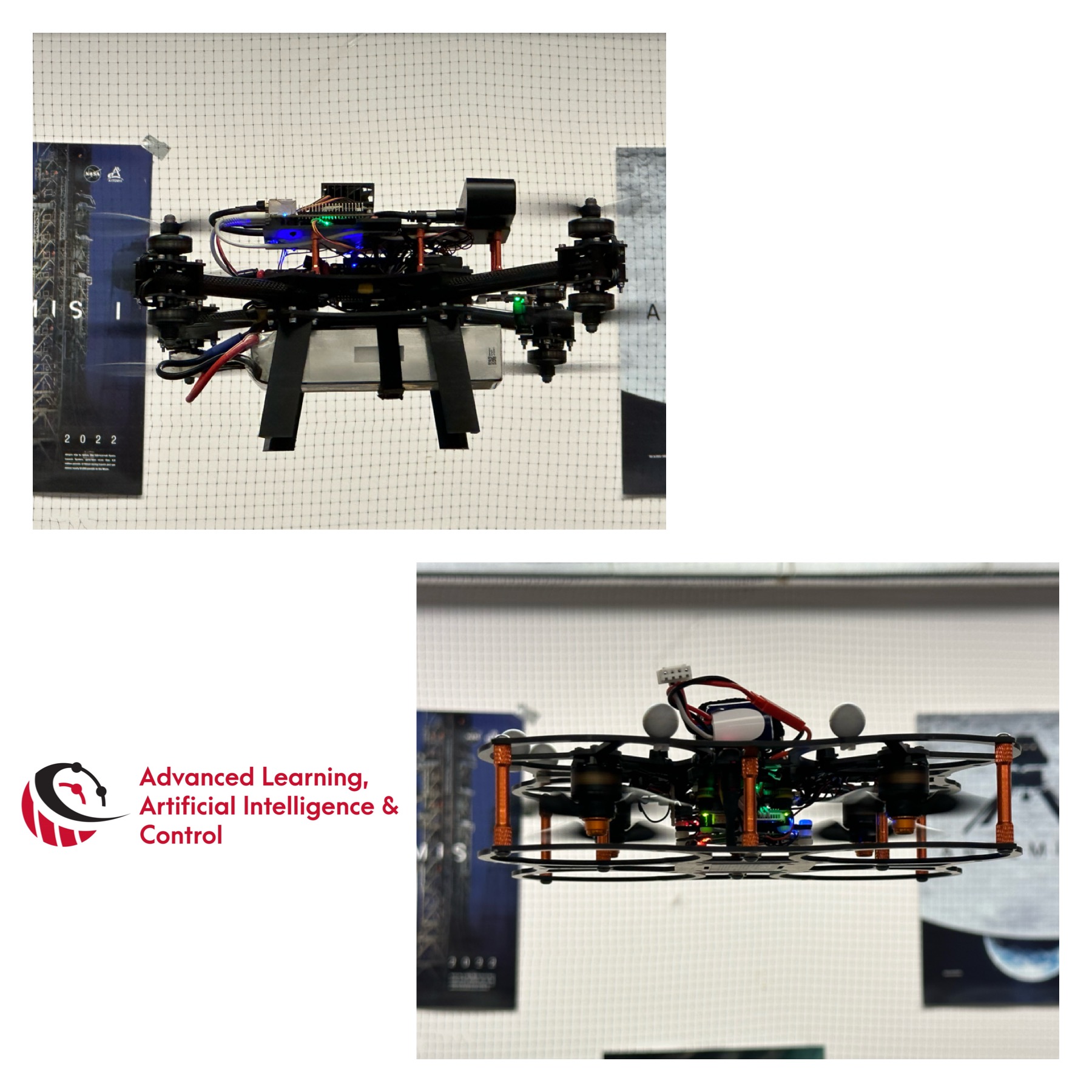

Advanced Air Mobility is a new form of transportation envisioning air taxis soaring over traffic, emergency response, and disaster relief, aided by unmanned aerial vehicles (UAVs), packages and supplies delivered autonomously by drones to hard-to-reach areas. The vision for AAM is that of a safer, accessible and affordable air transportation system. In our lab, we contribute to the realization of this vision by tackling several challenges involved in AAM: (1) path planning and collision avoidance with objects and other vehicles in this busy airspace; (2) planning around hazards, including weather; (3) multi-agent coordination, and (4) safe and assured autonomy.

We use faithful simulation environments to design and verify our strategies, and then we validate them on actual platform in the flight arena of our lab.

Ongoing Projects:

- Run time assurance (RTA) approaches for safe control of multi rotors UAVs in adverse and hazardous conditions (Founding source: Air Force Research Lab – AFRL)[AFRL ML-RCP Fall 23 Newsletter , student engagement].

- Safe and fault-tolerant kinodynamic motion planning for CPS.

Adaptive Space Systems

With a multi-million-dollar grant from NASA, the University of Houston opens the Inflatable Deployable Environments and Adaptive Space Systems (IDEAS2) Center, an aerospace engineering research center to support the space agency’s strategic goal of long-term space exploration, development, and utilization. The center focuses on conducting cutting-edge research on expandable, modular, and reconfigurable structures and adaptive space systems essential for sustainable human presence on the Moon and Mars in close collaboration with the adjacent NASA Johnson Space Center (JSC).

The Center’s research, in collaboration with JSC, will contribute to the robust and modular infrastructure and technologies that will enable humans to live and work in space, establish a lasting presence on and around the Moon, and pave the way toward Mars. The NASA Moon-to-Mars (M2M) campaign calls for the unsupervised operation of space systems, assets, and infrastructures to enable varying degrees of autonomy with enhanced capabilities, mission safety, and reliability.

In our lab, we are concerned with assuring the safety of spacecrafts proximity operations. This problem has seen increased attention due to the rapid growth of the commercial space industry and the rise of constellations of small satellites in Low Earth Orbit (LEO). These satellites are launched for various reasons, including geo-surveillance, data transmission, and missions involving ISAM/OSAM. Currently, unmanned spacecraft operate exclusively on human-issued commands. However, future missions will demand managing large constellations and complex missions without human intervention. Assuring the safety of these vehicles becomes paramount.

In our lab, we are concerned with assuring the safety of spacecrafts proximity operations. This problem has seen increased attention due to the rapid growth of the commercial space industry and the rise of constellations of small satellites in Low Earth Orbit (LEO). These satellites are launched for various reasons, including geo-surveillance, data transmission, and missions involving ISAM/OSAM. Currently, unmanned spacecraft operate exclusively on human-issued commands. However, future missions will demand managing large constellations and complex missions without human intervention. Assuring the safety of these vehicles becomes paramount.

We offer various projects in this field, combining novel analytical tools, design processes, control methodologies, and machine-learning-based algorithms with space applications.

Ongoing Projects:

- Generalizable docking, Safe spacecraft rendezvous and proximity operations (Founding source: NASA MIRO Inflatable Deployable Environments and Adaptive Space Systems (IDEAS2) Center, press release).

Superconductor manufacturing

We perform research on process control and machine-learning methods for real-time data analysis to achieve high manufacturing yield for superconductor or metal additive manufacturing projects at the Advanced Manufacturing Institute at the University of Houston.

Metal Organic Chemical Vapor Deposition (MOCVD) offers great potential for high yield rapid fabrication of High Temperature Superconductor (HTS) tapes. The MOCVD process is able to produce high quality HTS tapes allowing large deposition area. In this process, semiconductor precursors in gas phase thermally decompose upon contact with a heated substrate forming a superconductor film. MOCVD is a versatile process allowing large scale production of HTC coated conductors (CCs). However, superconducting tapes manufactured with conventional MOCVD suffer from large variations in the current critical density Jc due to potentially significant variability in the processing conditions of the MOCVD reactor that occur over time. The MOCVD process is sensitive to these variations resulting in structural and chemical compositional disparities along the length of the tape. A novel advanced reel-to-reel MOCVD (AMOCVD) system that has been developed at UH is able to scale up production of moving high quality long thick REBCO tapes meeting higher critical current density Jc requirements. Manufacturing of high-quality REBCO tapes of large thickness at scale with excellent homogeneous magnetic field properties based on desirable crystalline orientation and film morphology remains a challenge.

Ongoing Projects:

- Real-time learning and process control for high performance advanced MOVCD system